QE/5S

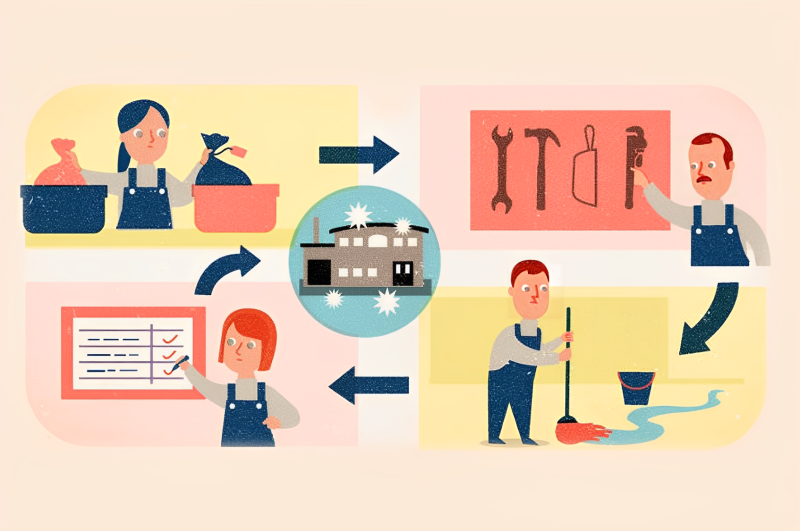

5S is one of the first tools that can be applied in a company that is starting to get into the continuous improvement culture. It helps to define the first rules to eliminate waste and maintain a work environment that is efficient, safe and clean.The good news is that 5S easy for everyone to start using, as it doesn’t require technical analysis, and can be implemented globally in all types of companies, ranging from manufacturing plants to offices, small businesses to large multinational organizations, and in both, the private and public sectors. Its simplicity, practical applicability, and visual nature make it an engaging aid for operators, directors, and customers alike.

5S ( SORT, SET IN ORDER, SHINE, STANSARDIZE, SUSTAIN )

5S is the perfect tool to identify the first improvement projects in your company to eliminate waste. Although sometimes viewed as a housekeeping technique, it is actually an innovative management system that helps people think lean, paving the way for the adoption of Lean principles in the organization. And here’s the best part: implementing 5S is a breeze! With this logical, step-by-step guide, you’ll learn what the big deal about 5S is, how to devise an action plan for 5S implementation, and how best to wield this powerful tool for improved productivity, elimination of wasteful processes, and all-round development!

Button Text